Liquid-liquid Extraction and Stripping

LIQUID-LIQUID EXTRACTION AND STRIPPING

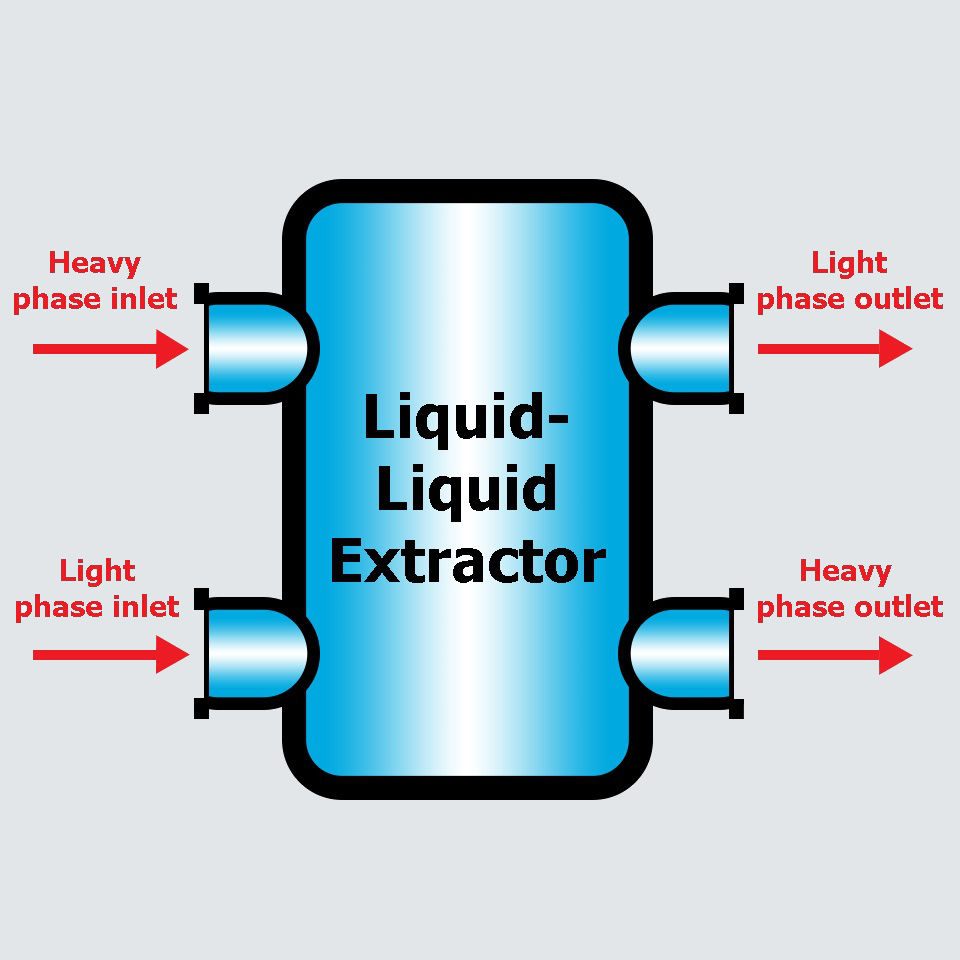

a) Liquid-Liquid Extraction Process

PSC S.p.A. Engineering & Contracting (PSC) is expert in Liquid-liquid extraction (LLE) also known as solvent extraction and partitioning: a method to separate constituents (solutes) of homogeneous liquid solutions. In this separation process, second liquid solvent is added which is immiscible or partially miscible with the feed and the solutes of the mixture are distributed between the two phases based on their relative solubilities. There is a net transfer of one or more species from one liquid into another liquid phase, generally from aqueous to organic. The solvent that is enriched in solute(s) is called extract; the feed solution that is depleted in solute(s) is called the raffinate.

This type of process is commonly used:

- After a chemical reaction as part of the work-up, often including an acidic work-up;

- If the distillation process is not feasible and convenient, because the component (solute) to be recovered is heat sensitive, non-volatile, high boiling point or azeotrope mixture cannot allow the purification.

(LLE) require a large consumption of possibly toxic solvent, which also when recycled in the system requires costly equipment. Thus, right selection of the solvent in achieving a sustainable process is required and it creates challenges to the large-scale industry implementation of the process.

If the aim of the process is to achieve a pure extract, the LLE as a downstream process is most often only the initial step. Further purification, such as distillation, crystallization or second extraction might be needed.

(LLE) has several industrial applications:

- Fermentation and algae broths (carboxylic acid, acetic acid, algae oil extraction);

- Removal of high boiling organics from wastewater (Phenol, amine, aromatics) that cannot treat by conventional and common process treatment;

- Removal of carboxylic acid (acetic, formic acid, succinic acid, valeric acid from fermentation yeast, pelargonic acid from bio oil processing);

- Protein separation and purifications (recovering of antibiotics, amino acid, steroids from fermentation broth);

- Essential oil extraction (bio-oil is produced from: biomass pyrolysis);

- Agricultural chemical extraction (herbicides and pesticides);

- Recovery reaction products caprolactam and adiponitrile from nylon production;

- Food industry applications (flavors, fragrances);

- Neutralizing acids and bases (as acrylates, nitrated organics and chloro-benzene compounds).

Type of liquid-liquid extraction process can be performed by means following methods:

- Direct centrifugal extractor;

- Settlers (gravity and mixing type);

- Column (pulse, stirred, rotating contactors).

ENCYCLOPEDIA OF CHEMICAL ENGINEERING

b) Stripping Process

The stripping process is a physical separation process where one or more components are removed from a liquid stream by a vapor stream. In industrial applications the liquid and vapor streams can have co-current or countercurrent flows. Stripping is usually carried out in either a packed or trayed column.