Automation & Control Engineering

PSC S.p.A. Engineering & Contracting (PSC) is a customer oriented company offering a wide range of flexible services to suit every client’s needs.

PSC's Automation & Control Engineering Department carries out the following activities:

- General specifications of plant control systems based on PLC, PAC, DCS and ESD systems (General Philosophy Plant Control, Emergency Stop System, Telecommunication Systems, Functional Design Specification);

- Analysis of the hierarchy of the control system block diagram and architectural;

- Definition, or technical support in the definition, of the control system;

- Detailed design of the overall architecture of the control and safety system;

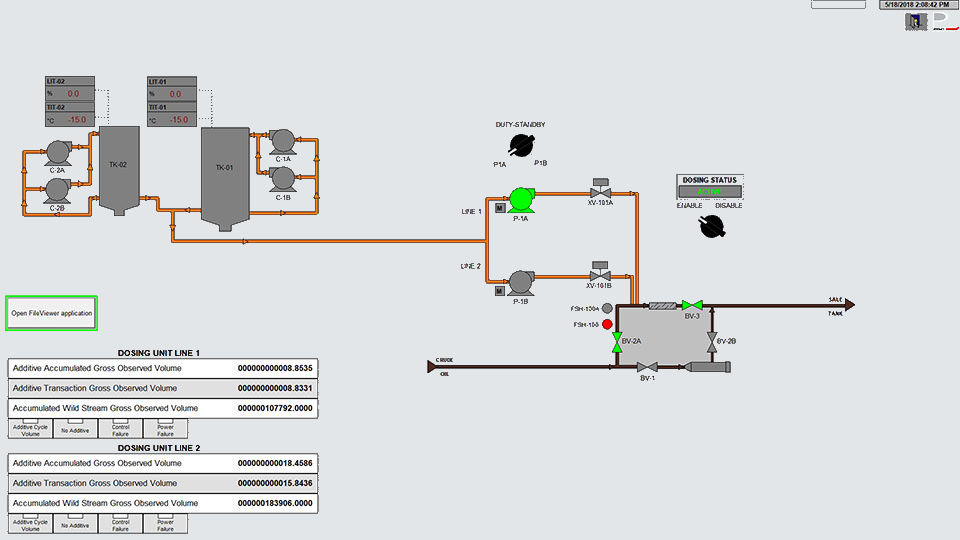

- Basic layout of the control room and analysis of solutions for human-machine interface;

- Review and check of the technical documentation issued by suppliers, in order to verify that what will be provided and performed is in compliance with the requirements of project standards and design specifications;

- List of input/output (including conventional points, smart, FF and soft);

- List of alarms and set points;

- Risk analysis and integrity requirements for the system (SIL);

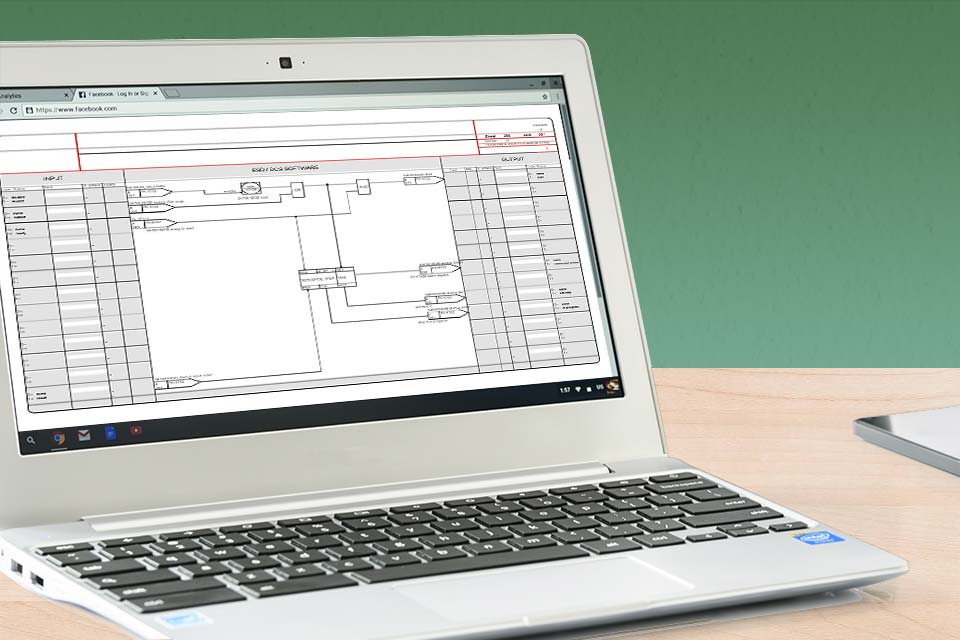

- Detailed design of the hardware of the control system, including dimensioning of electrical and electro-mechanical components with the system, the design of the control panel, wiring diagrams, loop diagrams;

- UPS sizing and load lists;

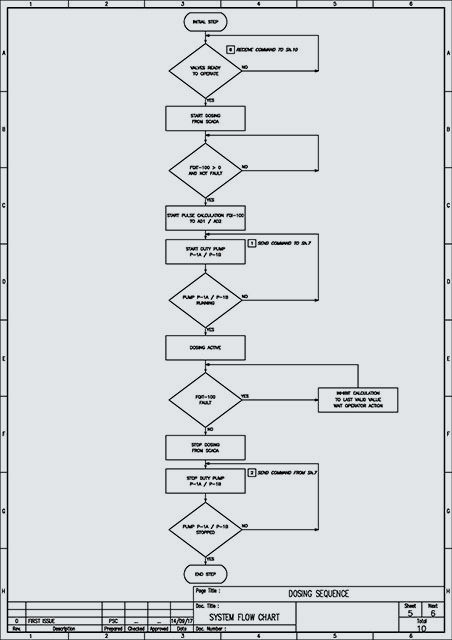

- Detailed design of the software of the control system including logic diagrams AND/OR, matrix effects cause, sequence diagrams;

- Drawing up of control logics and advanced control strategies (Control Loop Narratives);

- Issue of FAT and SAT procedures;

- Development and Implementation of database for Control System;

- Configuration of advanced control loop;

- Configuration of the control logic (or shut down) and sequences of automation;

- Configuration of the graphic pages, alarms pages, reports and trends;

- Testing at the factory (FAT) and factory tests integrated with third-party systems (IFAT);

- Coordination and assistance to commissioning, start-up, on-site testing (SAT);

- Training, technical support and remote support.